V4 Racing Engines

- Scat V4 Racing Engines For Sale

- V4 Midget Racing Engines

- V4 Racing Engines

- Racing V4 Engines

- V4 Racing Engines

Simon Skinner is Norton’s Executive Director and Head of Design, who joined the company in February 2009 from Triumph as one of Stuart Garner’s first appointments after acquiring Norton the previous year. Here he explains the genesis of the 1200cc V4 that’s got the whole world talking.

The engine has been developed in conjunction with the former Vepro design consultancy in nearby Coalville, 10 miles away from the Norton factory at Donington Hall. Founded in 1999 by Triumph’s former Head of Engine and Transmission Design, Neil Wright, Vepro was acquired in October 2014 by design industry giant Ricardo to form Ricardo Motorcycles, and has been working on the new Norton projects since December of that year. An industry leader ever since its foundation in 1915, Ricardo has worked ever since then on developing new vehicles with any number of wheels for companies all over the world, from Ferrari to JCB, Volkswagen to Piaggio. It’s worked for most major motorcycle manufacturers including Triumph and BMW, for which it developed the C650 range of scooters, as well as the six-cylinder K1600GT and the K1300S motors. Now it’s the turn of Norton, as Simon Skinner explains.

With that said, a new V4 engine would aim squarely at the VFR’s well-earned sport-touring customer base. Similar to the latest Africa Twin, a VFR800 revamp could require a displacement bump to. 5696 engines are available from RacingJunk Classifieds. Search our selection of engines for sale for 5696! You can have the greatest chassis in the world, but the power plant for your race vehicle is the engine. From crate engines for drag racing, circle track racing, street cars, and off-road, from small block V8 to sealed engines, from LS drag race beasts with modified camshafts to superchargers, from sealed factory crate engines to hand-built customs, the engine you need to win can be found here. The earliest automotive use of V4 engines were in Grand Prix racing (later called 'Formula One') cars. One of the pioneering V4 engines was in the 1898 Mors rear-engined car built in France. Nelson Racing Engines 9318 Oso Ave. Chatsworth CA 91311 Phone 1(818) 998-5593.

“The V4 project officially started 18 months ago, but it’s been in our minds for a long time,” Skinner begins. “When I first started with Norton seven years ago we had some very early discussions about the type of bikes we wanted to develop, including a V4. But we had to get the Commando into production properly first, and get the worldwide distribution sorted, which we’ve now done. But also, because the growth rate of Norton has been so fast, we never really had the cash to invest in research and development until 18 months ago, when we first became profitable — we’d been growing at 50-60 percent year-on-year, so all our money had been tied up in building volume.

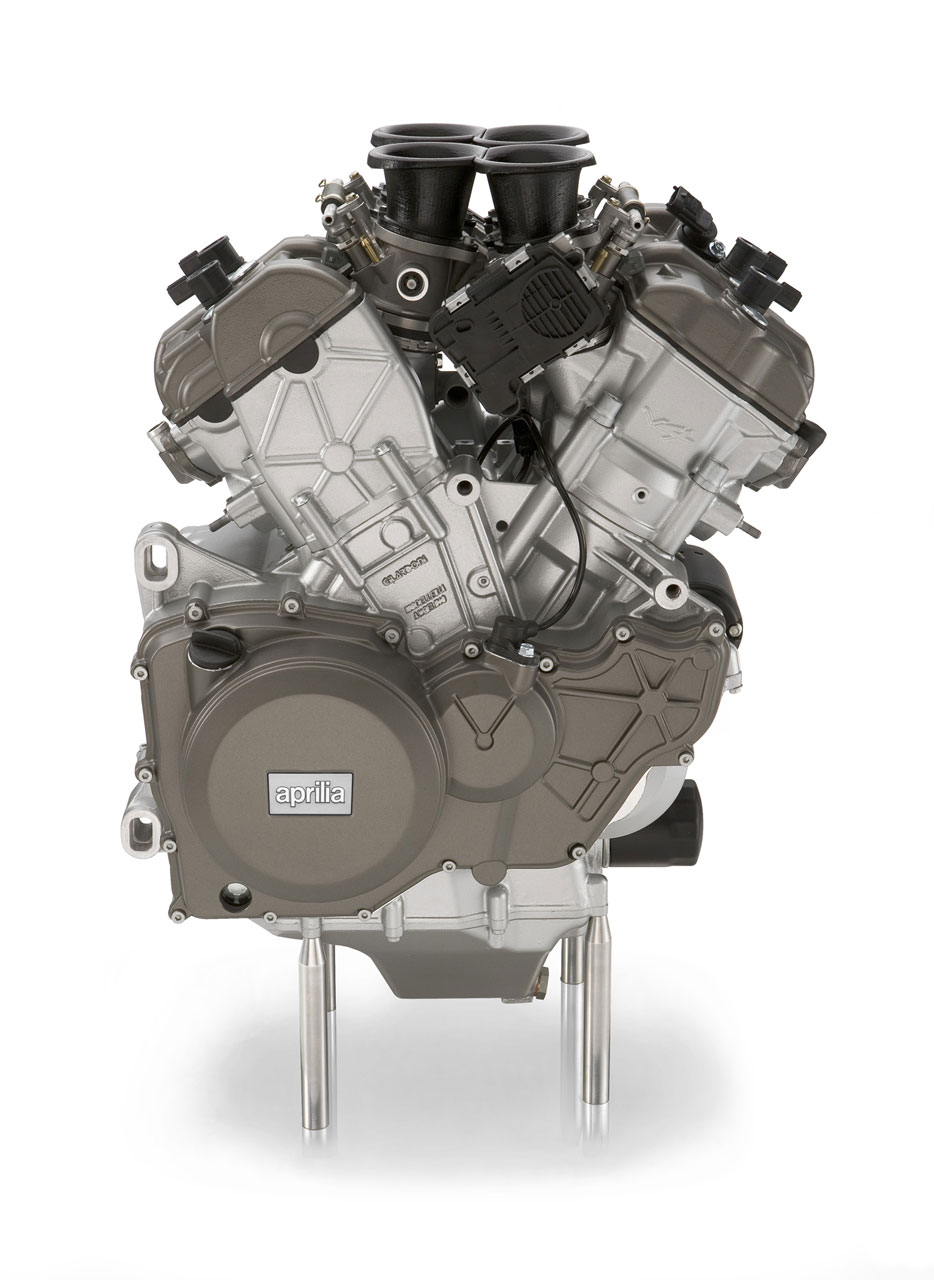

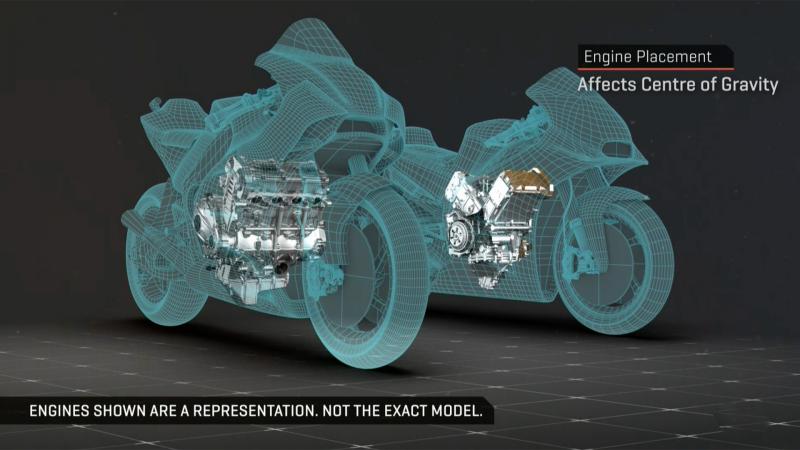

“So now we’ve been able to focus better on the V4 project that we’ll launch at the Birmingham NEC Show this coming November, with production starting sometime in 2017. The engine is being developed in conjunction with Ricardo, and it’s coming together really well as we’ve been able to design a bike and a motor together at the same time as an integrated, really compact package, which is quite a rare opportunity — rather than having to wrap a frame around an existing engine. We’re using the Aprilia-engined Norton TT racer as the basis for the chassis design in terms of developing geometry, as well as developing electronics and a bit of ergonomics, too.

“Of course, if you have a fast TT racer you’ll have a fast road bike, so that works really well even though the 1000cc RSV4 motor has a slightly narrower 65° cylinder angle, whereas the 1200cc Norton V4 has ended up at 72°. But in spite of being 200cc bigger our motor is actually physically smaller than the Aprilia, so it fits in largely the same hole that the Aprilia left in the frame, which of course is very good. But that’s not because it’s an ultra-short stroke design, it’s just the way we’ve designed the architecture of the motor, with the biggest difference being that the balance shaft on the Norton V4 is beneath the crankshaft so that it ends up being a really short motor, whereas the Aprilia’s is in front of the crankshaft, making it longer. So we can get our 1200cc engine in the same space in the chassis that they got their 1000cc motor.”

“I can’t speak high enough about Aprilia after working with them on the RSV4, but obviously one of the problems of a narrow-angle 65° V4 like that is the throttle bodies tend to stick up higher, which makes the overall engine package taller. That’s one reason for the Norton having a wider 72° vee angle, which aside from giving us a little better packaging around the throttle bodies, also gives us space to get more power from a slightly bigger airbox. Our V4 engine has four valves per cylinder — paired, not radial — and is obviously liquid-cooled with double overhead cams per cylinder bank, driven by chain. It’s not gear driven, since gears are too noisy for a road engine. We’ve paid a lot of attention to keeping the height of the engine down, so we’ve designed an ever so slightly different a camdrive layout to the Aprilia, which lets us take 15mm off the height of the motor compared to the RSV4. The targeted weight of the engine is about the same as the Aprilia, around 160-165lb – but then again it’s 20 percent bigger in capacity with a wider Vee-angle, so that’s quite a tough target.”

“The chassis will be a hand-polished aluminum tube frame made from aerospace aluminum and billet parts, welded in house and like the TT racer with a single sided swingarm and Öhlins suspension, but it’s different to the SG5 in that we’ve got a slightly more compact rear subframe. There are lots of upsides to a V4 motorcycle engine, but like any other engineering design there are downsides as well, and with a V4 you’ve got a rear cylinder head parked between your legs. This naturally means you get a bike that’s wider down the middle, which is not what you want — so we’ve looped the frame rails over the rear cylinder bank, then down and around beneath. You’ve got a slim feeling when you sit on it and it makes the bike very compact down the middle. Since the key model we’re aiming to produce with it is a sort of two-wheeled Aston Martin, a kind of hypersports tourer, the bike has always been designed with a passenger in mind. However, although the frame structure and the rear subframe will be strong enough to take a passenger, the first model will be a single-seater, so it’ll all be about the style and the speed and the noise!

“It’ll be a premium motorcycle, so besides the fully adjustable Öhlins suspension everything on any Norton V4 will be strictly the best — full carbon bodywork, Brembo monoblock radial brakes, BST carbon wheels, hand-polished billet triple-clamps, a titanium exhaust, full color TFT dash, a choice of carbon fiber or billet aluminum for the single-sided swingarm, LED headlamps with angel eye daytime running lights, and a full set of electronic rider aids including traction control, anti-wheelie and so forth. It needs to be an appropriate level of technology, so we’ll need ABS, but we don’t need 10 different anti-wheelie settings — it’s not what Norton’s about. With Ricardo handling the design work, we’ll go straight to production tooling for the V4 — we won’t make any prototypes, but will tool it up straight away. The problem with prototypes is, if I go and billet machine the crankcase and it cracks in the middle, is it because of the machining, or is it that I designed it wrongly?! Knocking off a million pounds to tool up a motor makes it a big deal, but you’re never quite sure when you do prototypes why it’s failed, and if it passes I’ve got to do the due diligence and testing all over again on a production part. So we’ll go straight to production spec, and make sure we thoroughly test the result before releasing the bike to customers. We’ve not had an engine running on the dyno yet, but that’ll happen before the end of the year.”CN

For more Cycle News Sport Bike motorcycle reviews, click HERE.

Scat V4 Racing Engines For Sale

The HIGGS HAWK V4 E330J/G Diesel is a clean sheet combined cycle, spark ignition, multi-fuel solution for the needs of today. Weighs in at only 306lbs / 139kgs.

HAWK E330J/G Features

V4 (350hp-500hp) E-330J/G and E-330J/G-T clean sheet design engines. These engines will demonstrate our unique design for achieving the needed horsepower while keeping the weight of the jet burning engine at or below similar AVgas versions of these engines.

COMBINED CYCLE PISTON OPERATIONAL ADVANTAGES

- Conventional 4 cycle wet sump lubrication

- No valve gear

- Low thermal loading of the piston

- High durability with low exhaust emissions

- Compact low mass design

- Extended oil change periods (oil does not degrade)

- Extended maintenance intervals (less parts to maintain)

- New concept in high performance aircraft engine

- Unique operating method

- Low part count for high life

- Extremely high power to weight

- Minimum vibration

- Low noise and heat signature

- Also available as forced induction / E-330J/G-T – 500hp

- Weighs only 306lbs / 139kgs

We are now taking orders for the Hawk V4. Use the link above to send us an email and get on the list and in the production queue. Once a deposit is initiated to secure your serial # there is a 12-16 weeks lead time prior to delivery.

V4 Midget Racing Engines

A very big punch from a small package

V4 Racing Engines

One of the most attractive features of the HAWK V4 E330J/G is its size. As you can see from the images opposite. They illustrate very clearly the benefits of the added horsepower in a much smaller package. Shown here is an overlay of the Lycoming IO-540. Need we say more…

For OEM’s and builders alike, one of the biggest challenges is the firewall forward and getting everything to fit. And that’s not including the challenges and headaches associated with forced induction installs. The Hawk V4 really lends itself with ease to the introduction of forced induction which is why we offer the Hawk as a E330J/G-T. The turbo version provides a mission ceiling of upto 50,000′ and 500hp.

Performance

Our design enables combined cycle engines to compete with four-cycle engines in terms of fuel economy, especially under cruise conditions. The crankcase, freed from any gas exchange functions, is well lubricated; the working processes being sealed above the piston. Isolation of the crankcase also permits a full pressure lubrication system to be used, as in four-cycle engines.

Reliability

Inherent piston cooling characteristics of the combined cycle piston design offer a major durability advantage over conventional two-cycle engines, allowing much leaner fuel delivery than can be sustained with traditional crankcase scavenging, where usually piston overheating and consequent seizure are common. This technology operates without complex mechanical components such as cams, valves mechanisms and the other various precision components necessary to operate them.

The absence of these mechanical components eliminates a large number of moving parts, thereby considerably reducing the costs and maintenance requirements, whilst significantly increasing reliability and retaining the simplicity of the two cycle engine. With this combined cycle design two cycle engine technology, combined with the enormous benefits together with their appealing simplicity, a new generation of light weight high performance power plants can be achieved. Which until now would have been almost impossible.

Fuel Type & Consumption

This platform of engines has been designed from the ground up to be a true multi-fuel unit.

Designed to run on industry standard Jet fuel (Diesel (EN 590), Jet A, Jet A-1, JP-5, DEF STAN 91-86, JP-8, DEF STAN 91-91, JP-8+100, Chinese Jet Fuel No 3)

Will also run and perform on all gasolines where necessary, 80,87,91,95 including 100LL along with all bio derivatives.

Hydrogen gas.

BSFC, 0.398 lb/hp-h (231g/kW-h) Pratt & Whitney PT-6 Turboprop by comparison is 0.507 lb/hp-h (308 g/kW-h) (on approach and idle 0.825 lb/hp-h (502 g/kW-h))

Efficiency & Economy

It is necessary to emphasize the importance of the very high volumetric efficiency of the traditional piston controlled ports employed by the standard two cycle engine. Until now no existing type of inlet valve could produce the essential requirements of presenting the maximum inlet area to the air in the minimum time.

The new design outlined below, significantly increases both the utility and the efficiency of the of the two cycle engine, which may now be more efficiently scavenged.

Racing V4 Engines

The port layout adopted concentrates the scavenge flow at the wall of the cylinder opposite the exhaust port. This compares with more evenly dispersed scavenge flows common in conventional engines. Scavenge flow within the cylinder provides, in effect, a form of stratified charging and explains improvements in fuel economy obtained with such a simple layout.

V4 Racing Engines

We are now taking reservations for the Hawk V4. Use the button above to send us an email and get on the list and in the production queue. Check the reservations page for lead times and availability here.